A- Test conditions:

Ensuring the complete installation of the network and the stability of the installed pipes at the installation site is equivalent to 17 hours, during which the temperature tolerance of the water and the test environment should not be more than 3 degrees Celsius.

B- Initial test: We put the closed pipe network under an initial pressure of 1/3 times the working pressure of the PN pipe for 12 hours. During these 12 hours, the pipe pressure will drop and the mechanical behavior of the pipe’s compressive expansion will reach its linear region. It is obvious that the pipes with the same working pressure in the network can be measured simultaneously by this test.

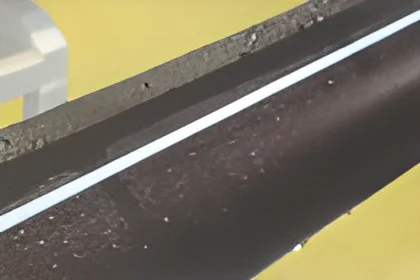

Linear behavior of compressive expansion of polyethylene pipe with respect to time in isotherm conditions

C – The final test of leakage measurement)

At this stage, as soon as the initial test time is over, we will again increase the network pressure to 1/3 times the PN of the pipes and measure the volume of water consumed. Then we keep this pressure constant in the network for 5 hours and measure the volume of water required to keep the pressure constant from the second hour to the third hour of the test. We also measure the volume of water required to keep the pressure constant from the fourth hour to the end, i.e. the fifth hour of the AV test (4-5).

D- Analysis of the results: After the above measurements, to ensure that the network does not leak, the following relationship should be established:

AV (5h-4h) 0.550 AV

(3h-2h)

If the relationship between the volumetric amounts of water used to stabilize the pressure is established as above, the pipeline in terms of measurement test

Leakage is considered acceptable

If the above relationship is not established, one or a set of the following factors are effective:

1- Line leakage

2- Excessive changes in temperature (more than 35)

Axial elongation of the pipe due to the pipe not being fixed in the installation position

Related Posts

Aqua pipe properties

The ability to use pigments allowed in contact with food (Food grade) in the inner…

Introduction to polyethylene

Polyethylene is a large molecule that is obtained from the chemical connection of ethylene gas…

Methods of further understanding of executive coaching and recognition of its factors

In the hour of freedom, when our choice of power is not limited and nothing…

Is pranking at work causing problems for your business?

In the hour of freedom, when our choice of power is not limited and nothing…